Aim

The aim of the project is to Create a conveyor belt system with automated start/stop functionality

Problem statement

Create an automated conveyor belt system that efficiently manages the transportation of goods within a manufacturing or logistics facility. The system should incorporate sensors for object detection, automated sorting mechanisms, and adaptive speed control to handle various types of products. The goal is to design a reliable and flexible conveyor system that improves production efficiency, minimizes errors in sorting, and enhances the overall throughput of the manufacturing or distribution process.

Material used

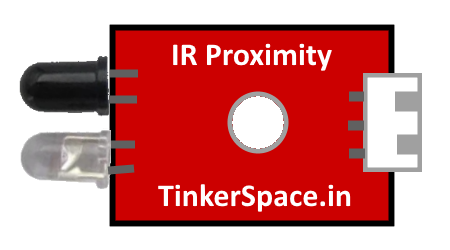

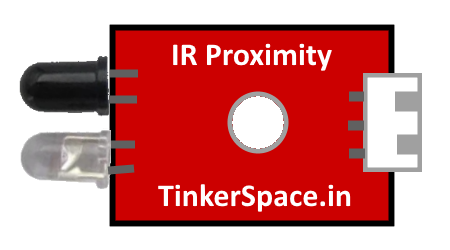

Input: 2 IR Proximity Sensor

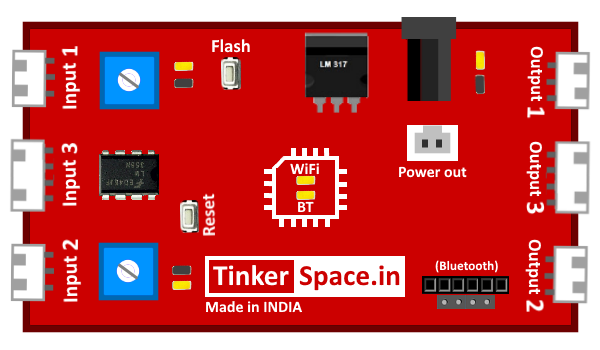

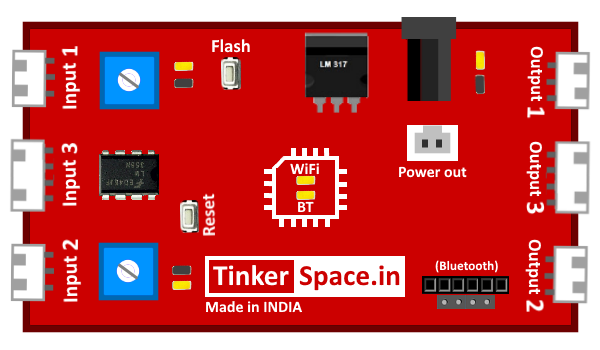

Brain: TinkerSpace Brain Board

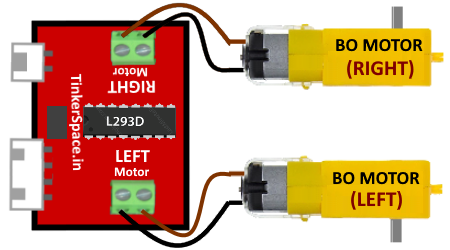

Output: Motor Driver and 2 Gear Motor and Servo Motor

Battery: 5V Lithium-ion rechargeable battery

Component description

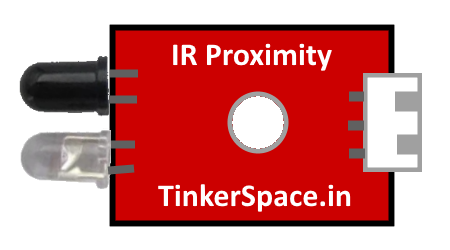

2 IR Proximity Sensor

The function of IR proximity is to detect the object and send the signal to the Brain unit (TinkerSpace board).

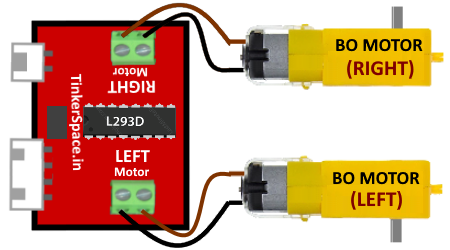

Motor Driver+2 Gear Motor

Motor driver is used to control the motors to rotate either CLOCKWISE or ANTI-CLOCKWISE.

Gear Motors are used to move the conveyor belt.

Servo Motor

Servo motor is used to move the item from conveyer belt to storage areas

TinkerSpace Brain Board

TinkerSpace board acts as brain of this project, its function is to monitor Push Buttons and control motor driver and gear motors.

Battery

5V Lithium-Ion battery is used to power-up this project

Working description

Case 1: When the object is detected, IR Proximity 1 sensor turns ON and sends the signal to the brain board. The brain board rotates both the gear motor clockwise

Case 2: When the no object is detected, IR Proximity sensors turns OFF and sends the signal to the brain board. The brain board signals the gear motor to stop from moving.

Circuit Design (DesignSpace)

Step 1: Connect 2 IR Proximity Sensor to input 1 and input 2

Step 2: Connect MOTOR DRIVER(2 gear motors) to output 3 and servo motor to output 1

Step 3: Connect supply and test project.